| number | Mold Name | specifications | material quality |

| ★ Single parting mold | Two the first mock examination, side gate, ejector pin | 190×180×260 | All aluminum alloy |

| ★ Double parting mold | Two the first mock examination, point gate, push plate push out | 230×160×180 | All aluminum alloy |

| Double parting mold | Fixed distance pull plate double parting surface injection mold | 230×160×180 | All aluminum alloy |

| Double parting mold | Hook type double fractal surface injection mold | 210×160×180 | All aluminum alloy |

| Double parting mold | Fixed distance pull plate, point gate, push plate push out | 200×160×250 | All aluminum alloy |

| Double parting mold | Plastic brush injection mold for demolding with fixed distance push plate | 230×160×250 | All aluminum alloy |

| Double parting mold | Injection mold for the detachment of condensate from the gate at the break point of the diversion channel | 240×160×200 | All aluminum alloy |

| Double parting mold | Using a pulling rod to pull the broken point of the sprue, the pouring material falls off the injection mold | 240×165×200 | All aluminum alloy |

| Double parting mold | Injection mold for the detachment point of the diversion channel push plate and the detachment of the pouring gate condensate | 240×165×210 | All aluminum alloy |

| Double parting mold | Fixed distance pull rod type double parting surface injection mold | 230×160×200 | All aluminum alloy |

| ★直角模 | Single parting surface: side feeding, push plate push out, right angle injection mold | 220×220×240 | All aluminum alloy |

| ★ Right angle mold | Right angle injection mold for ink bottle cap with automatic thread removal | 180×150×260 | All aluminum alloy |

| ★ Valve closure mold | Three petal injection mold with oblique slider and oblique guide pillar in the same moving mold | 210 ×170×220 | All aluminum alloy |

| ★ Valve closure mold | Injection Mold for Vertical Parting Surface Oblique Sliding Block Clamping Structure | 200×200×250 | All aluminum alloy |

| ★ Spring core pulling mold | Injection mold with short distance spring core pulling structure on both sides, eight shaped latent gate feeding, top rod ejection, and reset rod resetting | 230×230×250 | All aluminum alloy |

| Spring core pulling mold | Injection mold with spring side core pulling and hidden gate structure | 165×165×220 | All aluminum alloy |

| ★ Insert mold | Injection Mold with Double Parting Surface and Single sided Active Insert | 180×190×220 | All aluminum alloy |

| ★ Insert mold | Injection mold with double-sided movable insert spring for first resetting | 240×230×200 | All aluminum alloy |

| ★ Diagonal parting mold | The guide pillar is in the moving mold, and the slider is in the oblique parting structure of the fixed mold injection mold | 220×220×180 | All aluminum alloy |

| ★ Pushing pipe mold | Two the first mock examination, latent gate, push tube push out, reset rod reset | 200×220×260 | All aluminum alloy |

| ★ Pushing pipe mold | Injection mold for claw shaped gate push rod push tube joint demolding | 250×170×220 | All aluminum alloy |

| External core pulling mold | Injection mold with thin film gate, inclined guide pillar, and inclined slider on the support seat of the fixed mold | 220×210×240 | All aluminum alloy |

| External core pulling mold | Injection mold with herringbone arc feeding gate, top rod ejection, inclined guide pillar in fixed mold, and inclined slider in moving mold | 200×200×320 | All aluminum alloy |

| Inner top mold | Oblique slider push rod push out type internal core pulling injection mold | 200×270×165 | All aluminum alloy |

| Internal core pulling mold | Two pieces of the first mock examination, inner core pulling injection mold with inner concave inclined slide | 310×150×170 | All aluminum alloy |

| Reset the module first | Hinge type first reset injection mold | 290×200×230 | All aluminum alloy |

| Secondary core pulling mold | Secondary sequential side core pulling injection mold | 190×200×220 | All aluminum alloy |

| Secondary ejection mold | Eight shaped swing bar advanced secondary ejection injection mold | 200×160×240 | All aluminum alloy |

| Secondary ejection mold | U-shaped restricted frame type secondary ejection structure | 240×160×220 | All aluminum alloy |

| Secondary ejection mold | Diagonal wedge pull hook type secondary pushing mechanism | 240×160×210 | All aluminum alloy |

| Secondary ejection mold | Swing block pull rod type secondary push out mechanism | 240×160×220 | All aluminum alloy |

| Hot runner mold | Typical hot runner model | 220×180×200 | All aluminum alloy |

| Hot runner mold | Internally heated hot runner mold | 320×180×200 | All aluminum alloy |

| Hot runner mold | Externally heated hot runner mold | 320×180×200 | All aluminum alloy |

| Die casting mold | Aluminum die-casting mold | 220×190×190 | All aluminum alloy |

| Injection molding | Typical injection molding | 220×180×190 | All aluminum alloy |

| Injection molding | Upper feeding plunger type injection mold | 220×180×190 | All aluminum alloy |

| Injection molding | Lower feeding plunger type injection mold | 220×180×190 | All aluminum alloy |

| Injection molding | Powder metallurgy injection mold | 220×160×250 | All aluminum alloy |

| Compression molding | Single parting surface compression mold | 220×160×160 | All aluminum alloy |

| Compression molding | Double parting surface compression mold | 220×160×240 | All aluminum alloy |

| Compression molding | Vertical parting surface compression mold | 210×180×170 | All aluminum alloy |

| Compression molding | Simple semi overflow pressure molding mold | 180×120×140 | All aluminum alloy |

| Compression molding | Simple non overflow compression molding | 180×140×140 | All aluminum alloy |

| Compression molding | Fixed compression molding | 160×160×240 | All aluminum alloy |

| Compression molding | Spherical handle compression molding mold | ¢140×200 | All aluminum alloy |

| Blow molding mold | Combination blow molding mold | 210×160×120 | All aluminum alloy |

| Blow molding mold | Press in blow molding mold | 200×150×140 | All aluminum alloy |

| Blow molding mold | Blowing Mouth Blowing Mold | 200×160×160 | All aluminum alloy |

| Blow molding mold | Blowing Mouth Blowing Mold | 200×170×140 | All aluminum alloy |

| Blow molding mold | Screw fastening blow molding mold | 230×180×140 | All aluminum alloy |

| Vacuum molding | Vacuum vacuum molding | 200×180×160 | All aluminum alloy |

| Vacuum molding | Compressed air molding mold | 200×180×160 | All aluminum alloy |

| Extrusion mold | Core rod extruder head (film extrusion) | ¢140×200 | All aluminum alloy |

| Extrusion mold | Cross extruder head (pipe extrusion) | ¢140×200 | All aluminum alloy |

| Extrusion mold | Straight tube extruder head (pipe extrusion) | ¢140×180 | All aluminum alloy |

| Extrusion mold | Elbow extruder head (pipe extrusion) | 150×130×130 | All aluminum alloy |

| Extrusion mold | Side extruder head (pipe extrusion) | 165×150×120 | All aluminum alloy |

| Extrusion mold | Spiral extruder head (thin film extrusion) | ¢160×200 | All aluminum alloy |

| Extrusion mold | Rotating extruder head | 200×160×140 | All aluminum alloy |

| Extrusion mold | Squeeze type wrapping machine head (wire extrusion) | 200×160×120 | All aluminum alloy |

| Extrusion mold | Sleeve type wrapping machine head (wire extrusion) | 150×150×110 | All aluminum alloy |

| Extrusion mold | Streamlined nose | ¢110×230 | All aluminum alloy |

| Extrusion mold | Plate type machine head (profile extrusion) | ¢140×150 | All aluminum alloy |

| Modular structure 1 | Injection Mold for Sliding Plate Core Pulling Structure | 200×170×170 | All aluminum alloy |

| Modular structure 2 | The basic structure of hydraulic core pulling mechanism | 200×160×180 | All aluminum alloy |

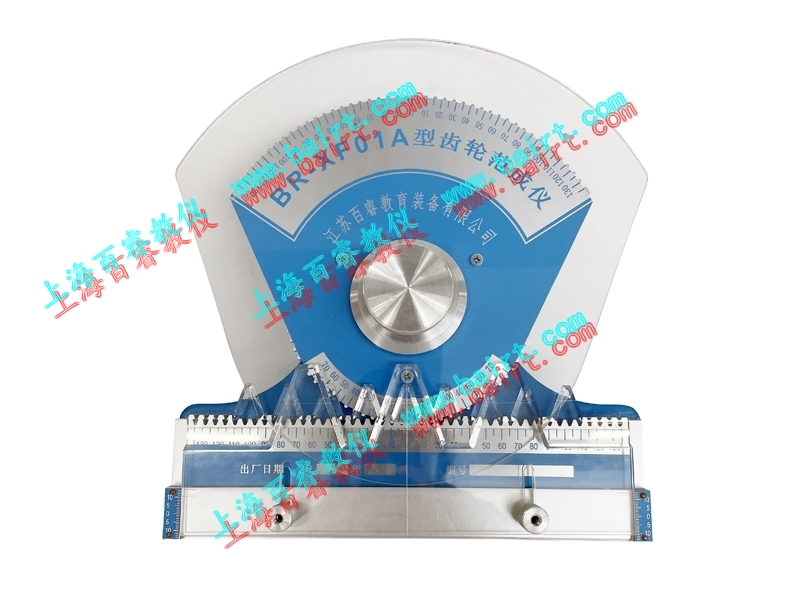

| Modular structure 3 | Gear shaft and rack inclined core pulling mechanism | 200×160×180 | All aluminum alloy |

| Modular structure 4 | Spring core pulling and end face limiting mechanism | 200×160×180 | All aluminum alloy |

| Modular structure 5 | Spring fixed mold core pulling, roller locking mechanism | 220×200×180 | All aluminum alloy |

| Modular structure 6 | Spring compression inclined core pulling mechanism | 220×180×190 | All aluminum alloy |

| Modular structure 8 | Injection Mold with Dynamic Demolding Structure for Lateral Thread Removal | 220×180×190 | All aluminum alloy |

| Modular structure 9 | Injection Mold for Dynamic Grinding Structure of Axial Thread | 220×180×190 | All aluminum alloy |

| Modular structure 10 | Injection Mold for Hydraulic Transmission Rack and Gear Unthreaded Structure | 220×180×190 | All aluminum alloy |

| Modular structure 11 | Injection mold for rack and pinion thread removal structure | 220×180×190 | All aluminum alloy |

| Modular structure 12 | Injection mold for large pitch spiral rod and gear thread removal structure | 220×180×190 | All aluminum alloy |

| Modular structure 13 | The simplest demolding structure injection mold | 240×180×190 | All aluminum alloy |

| Modular structure 14 | Push out guiding parts in the structure (four types) | 200×180×120 | All aluminum alloy |

| Modular structure 16 | Push rod shapes (seven types) | ¢50×200 | All aluminum alloy |

| Modular structure 17 | Conical push rod | 120×120×240 | All aluminum alloy |

| Modular structure 18 | Cross section shape of push rod (eight types) | 長250 | All aluminum alloy |

| Modular structure 19 | Top rod fixation method (six types) |

| All aluminum alloy |

| Modular structure 20 | Eight types of stop rotation patterns for threaded plastic parts |

| All aluminum alloy |

| Modular structure 21 | Top pole doubles as reset pole structure |

| All aluminum alloy |

| Modular structure 22 | Spring return structure injection mold |

| All aluminum alloy |

| Modular structure 23 | Injection Mold for Pushing Tube and Pushing Structure |

| All aluminum alloy |

| Modular structure 24 | The relationship between the shape and size of the push tube |

| All aluminum alloy |

| Modular structure 25 | Injection Mold for Pushing out Structure of Plastic Parts Using Concave Mold |

| All aluminum alloy |

| Modular structure 26 | Pushing block pushing structure |

| All aluminum alloy |

| Modular structure 27 | Injection Mold for Oblique Push Rod Ejection Structure |

| All aluminum alloy |

| Modular structure 28 | Injection mold, one of the push tube ejection structures |

| All aluminum alloy |

| Modular structure 29 | Injection mold for push rod driven helical gear structure |

| All aluminum alloy |

| Modular structure 30 | Injection Mold with Rotating Pushing Plate Pushing Structure |

| All aluminum alloy |

| Modular structure 31 | Central valve pneumatic ejection structure injection mold |

| All aluminum alloy |

| Modular structure 32 | Secondary ejection structure injection mold |

| All aluminum alloy |

| Modular structure 33 | Floating core type secondary ejection structure injection mold |

| All aluminum alloy |

| Modular structure 34 | Ball type secondary ejection structure injection mold |

| All aluminum alloy |

| Modular structure 35 | Injection Mold for Pushing Plate and Pushing Tube Combined Ejection Structure |

| All aluminum alloy |

| Modular structure 36 | Injection mold with lateral demolding structure |

| All aluminum alloy |

| Modular structure 37 | One of the spring return mechanisms, injection mold |

| All aluminum alloy |

| Modular structure 38 | Spring return mechanism II injection mold |

| All aluminum alloy |

| Modular structure 39 | Hinged first reset structure II |

| All aluminum alloy |

| Modular structure 40 | Hinged first reset structure III |

| All aluminum alloy |

| Modular structure 41 | Pendulum type first reset structure injection mold |

| All aluminum alloy |

| Modular structure 42 | Ejecting a reset device injection mold |

| All aluminum alloy |

| Modular structure 43 | Ejecting a reset device injection mold (continued) | ¢70×270 | All aluminum alloy |

| Model 1 | Center sprue waterway (fixed mold section) | 250×250×110 | All aluminum alloy |

| Model 2 | Center sprue waterway (dynamic mold section) | 250×250×110 | All aluminum alloy |

| Model 3 | Side gate waterway (section) | 250×160×120 | All aluminum alloy |

| Model 4 | Thin Gate Waterway (Section) | 250×200×120 | All aluminum alloy |

| Model 5 | Center sprue cooling water circuit (section) | 250×250×160 | All aluminum alloy |

| Model 6 | Multi point Gate Cooling Water Circuit (Section) | 250×240×130 | All aluminum alloy |

| Model 7 | Central gate cooling water circuit (four section) | 150×150×150 | All aluminum alloy |

Return to homepage

Return to homepage Immediately call for consultation

Immediately call for consultation About Us

About Us Immediately consult online

Immediately consult online